|

Baoji Pelifly Titanium industry Co.,ltd

|

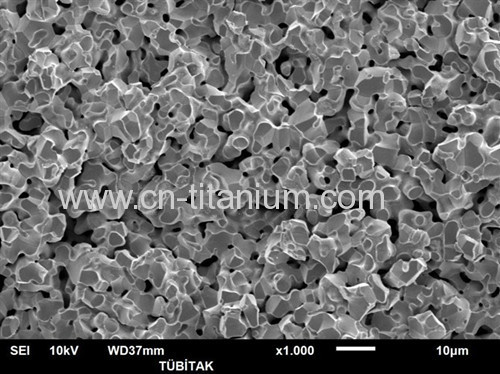

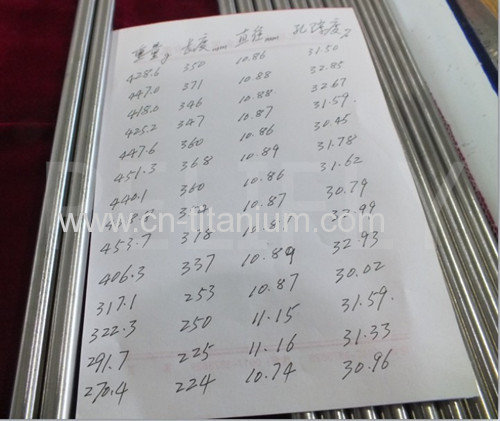

porosity: 30+/-3% tungsten rod diamater 10mm length between 200-300mm

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Specifications

Porous Tungsten rod & Bars

1.Materal Grade:W1, W2, TZM

2.Dia.10mm x 200-500mm L

3.Porosity: 30+/-3%

Specifications

Porous Tungsten rod & Bars

1.Materal Grade:W1, W2, TZM

2.Dia.2.5~12mm x 200-500mm L

Separation: 10%~45%

Mainly details

1. Materal Grade: Mo1,JMo2,Mo2,TZM

2. Specification Available: Dia.3.0~10mm x 200mm L or as per your requets 3. OEM Serviced offered, your drawing is available

4. Purity: 99.95% Min ~ 99.99% mAX

Mechanical property :

5. Boiling: 5927°C

6. Melting: 3410±20°C

7. Moh's hardness: 7.5

8. Latent heat of fusion: 40.13±6.67kJ/mol

9. latent heat of sublimation: 847.8 kJ/mol(25°C)

10.Heat of Vaporization: 823.85±20.9kJ/mol(Boiling)

11.Resistance-temperature coefficient: 0.00482 I/°C

12.Electronworkfuncton: 4.55 eV

13.Modulus of Elasticity: 35000—38000MPa(wire)

14.Torsion modulus: approx 36000Mpa

15.Bulk modulus: 3.108×1011-1.579×107t+0.344×103t2 Pa

16.Shear elasticity: 4.103×1011-3.489×107t+7.55×103t2 Pa

17.Compressibility: 2.910-7 cm/kg

18 Application: industry,military,medical

19. Mill test certificate and OEM Service offered.

20. Made as per your requests

Product Description

Item name | Tungsten bar |

Standard | / |

Specification | Dia10*200mm |

Application | Industrial |

Surface | Polished |

Processing | milling |

MOQ | 10kg |

Features:

1. With stable high-temperature-proof function thermo stability

2. With good comprehensive performance

3. The melting point is 3000 Centigrade

4. The raw material is high-purity, and adopts the advanced technology,

5. Long service life

6. Mainly put into the machine use, such as the machine parts, and it is also used as the coating material

Chemical component / The tolerance of Diameter and length

Chemical Composition

Trade mark | W | Other elements (%) NMT | |||||||||

W1 | Other | Al | Cu | Fe | Mg | Mo | Ni | Si | C | N | O |

0.002 | 0.005 | 0.005 | 0.003 | 0.01 | 0.003 | 0.005 | 0.008 | 0.003 | 0.005 | ||

The tolerance of diameter and length

Diameter (mm) | Tolerance(mm) | Indefinite length (mm) |

30~50 | ±3.0 | 200~700 |

>50~80 | ±4.0 | 200~700 |

>80~110 | ±5.0 | 200~700 |

>110~150 | ±6.0 | 200~700 |

Forging bar and Spin forging bar

Diameter | Tolerance (mm) | Indefinite length (mm) | processing | ||

Forged bar | Machining bar | Polished bar | |||

11~18 | ±0.5 | ±0.3 | ±0.2 | 200~1000 | Spin forging |

>18~30 | ±1.0 | ±0.4 | ±0.2 | 200~1000 |

forging |

>30~40 | ±1.5 | ±0.5 | ±0.25 | 200~1000 | |

>40~50 | ±2.0 | ±0.65 | ±0.3 | 200~1000 | |

>50~60 | ±2.5 | ±0.8 | ±0.4 | 200~800 | |

>60~70 | ±3.0 | ±1.0 | ±0.5 | 200~800 | |

>70~80 | ±3.5 | ±1.2 | ±0.5 | 200~800 | |