|

Baoji Pelifly Titanium industry Co.,ltd

|

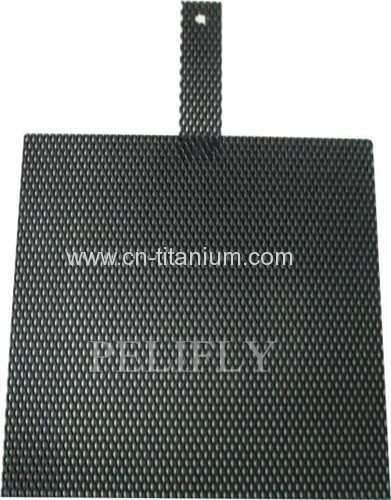

Titanium anode with lead dioxide coated GR1 titanium mesh 3*600*900mm

| Payment Terms: | T/T,L/C,WU,Paypal |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Titanium Anode , alos called MMO

including: Ru-Ir anode, IR-ta anode, Ru-ti anode, are widely use for sewage treatment, electrolysis, chlor-alkali

Item name: Lead dioxide coated titanium anode

Size: 2*600*900mm

Substrate: GR1 titanium Mesh

Oxygen Evolution potentail: 1.7V

Max current 5000A

Temperature: below 60°C

Expeated life; 5Y

Based materials: GR1 titanium

Caoting oxide: MMO+intermediate layer+Ta2O5+α-PbO2+βPbO2

Current density range ≦2000A/m2

Noble metai content: ≧8g;

Depth of coating: 0.6-1mm(one side)

Aplication: 1. Chromium plating and hard Chromium plating in stronger acid solution.

2. Chromate Treatment;

3. To make Chromatic acid; Perchlorate and periodate;

4.Electrolysis recovery and extraction of nonferrous metals in stronger acid solution;

5. Electrochemical oxidation synthetic organic compounds in acid solution;

6. Sewage treatment to remove COD.

Specifications

1.titanium anode,MMO titanium anode,titanium electrode

2.Size:1.0*45*220mm or as per

3.long life time

4.MMO coating: Iro2 , Ruo2, Ti '; Ru Ir Ti, Ir Ta

5. Application: for swimming pool disinfection, waste water, sea water

6. Coating: Ruthennium-Iridium, Ruthennium-Iridiun

7.Field : seawater electrolysis

8.current density: 200-500A/m2

The difference between Ir-Ta and Ru-Ir coating

Serial number | Use | Composition |

Ruthenium Iridium titanium anodes | Chlor-alkali ,sodium hypochlorite, and Organic compounds electrolytic synthesis, sewage treatment, Seawater desalination etc. Industry. | Base material: Ti Coating metal: Ru, Ir, Ti |

Tantalum Iridium titanium anodes | Electrolysis production of copper foil, aluminum foil, steel foil etc, electrolyze copper, zinc, nickel, etc. non-ferrous metal as anodes in the Sulfuric acid electrolytic medium. | Base material: Ti Coating metal: Ta. Ir. Ti |

Ruthenium titanium anodes | Chlor-alkali industry, caustic soda, Caustic potash, sodium chlorate, sodium, hypochlorite, etc. Chlorine salt electrolysis. | Base material: Ti Coating metal: Ru. Ti |

Ir-Ta coating

It resistance to oxygen electrodes, mainly usd for put oxygen reaction, especially suitable for acid electrolyte, such as in a certain concentration of sulfuric acid electrolyte, it has low oxygen, and it can be used to put oxygen electrolysis, also resistance to corrosion of chlorine, then it can be used to put oxygen and chlorine together electrolysis, such as seawater electrolysis, etc. It is a better electrode materials for acid medium put oxygen reaction. The coating electrode has been applied in electroplating industry etc, such as electrolytic copper auxiliary anodes, electrolytic zinc auxiliary anodes, cathodic protection auxiliary anodes.

Ru-Ir

This coating is used for electrolyte, which has high hydrogen and oxygen liquid, it has good resistance to oxygen corrosion, and suitable for ionic membrane electrolytic.